What corrosion resistance classes mean

Taking into account DIN EN 1993-1-4:2015-10/Eurocode 3 – Annex A

Stainless steel is available in many different variants that have different properties. Stainless steels have very different properties depending on the materials used and the composition of the alloys. While some are characterized by a high mechanical strength or good heat resistance, others are extremely corrosion resistant.

In order to classify stainless steels more easily with regard to their corrosion resistance and to be able to select materials appropriately, what are known as

corrosion resistance classes (CRC) are defined for constructions in steel structures. For example, these classes determine whether the expectations regarding the durability of structures are fulfilled.

The five corrosion resistance classes (CRC)

A total of five different corrosion resistance classes exist for stainless steels for the construction of steel structures. These are often abbreviated to CRC and written in Roman numerals. The classes determine how resistant stainless steel is to corrosive damage.

The following classes are defined:

- I: low

- II: moderate

- III: medium

- IV: strong

- V: very strong

The relevant standards for material selection according to CRC resistance classes

Until 2015, Building Inspectorate Approval Z 30.3-6 regulated material selection in Germany according to corrosion resistance classes.

The specification included a table of the different corrosion resistance classes used to select the material.

Since 2015, DIN EN 1993-1-4:2015-10/Eurocode 3 represents the relevant standard for material selection in Europe. It has been established

by CEN (European Committee for Standardization) and stands above national standards. The corrosion resistance classes according to DIN EN 1993-1-4:2015-10/Eurocode 3 – Annex A are mandatory for material selection for the construction of steel structures.

General Building Inspectorate Approval Z-30.3-6 as a German standard is still valid in the partial areas not governed by the European standard.

Calculating resistance classes

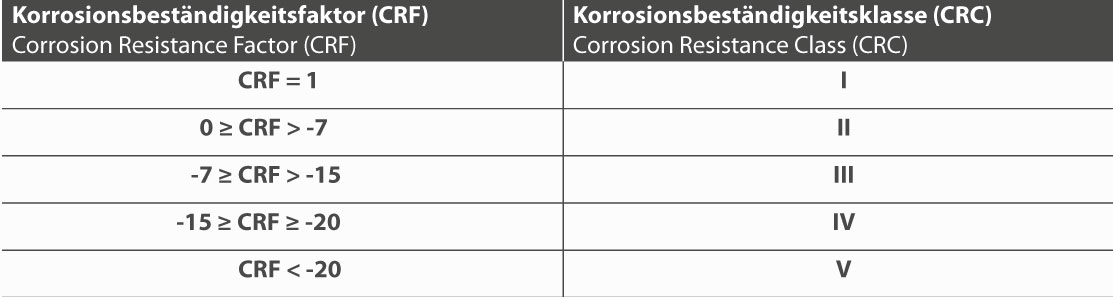

DIN EN1993-1-4:2015-10/Eurocode 3 describes how a corrosion resistance factor (CRF) is determined, which, in turn, determines the corrosion resistance class (CRC).

The CRF depends on the corrosiveness of the respective environment and can be calculated using the following formula:

CRF=F1+F2+F3

F2: Risk of exposure to sulfur dioxide

F3: Cleaning concept and exposure to washing by rain

Choosing suitable materials

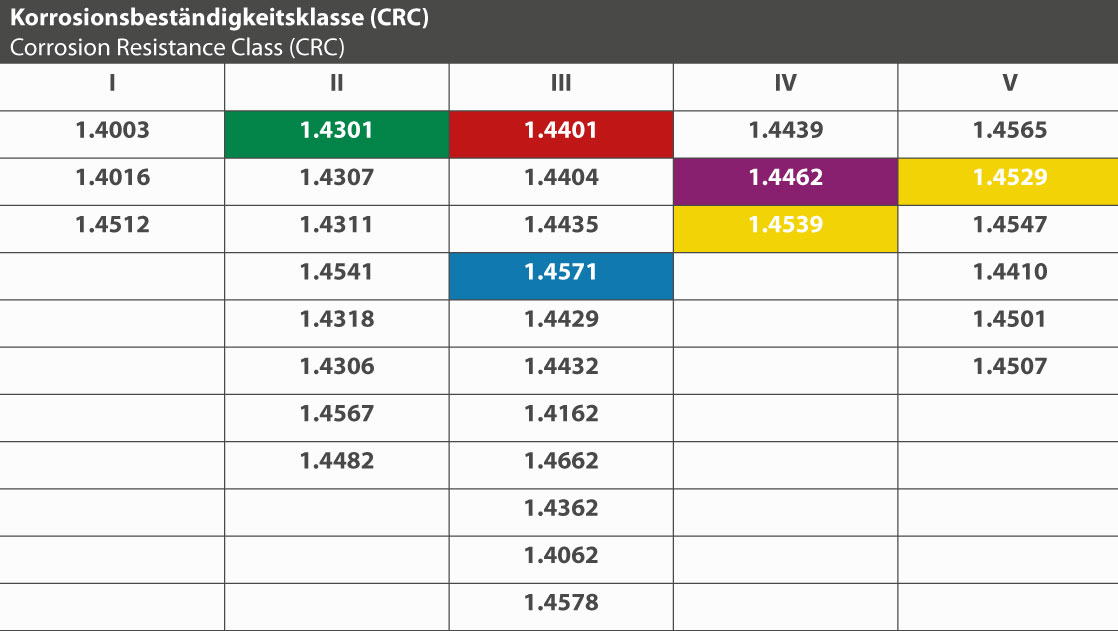

If the CRC corrosion resistance classes to be complied with are known, the following table can be used to select the appropriate material:

In your selection you should note that although steel grades of higher grades may be used in place of grades determined by calculating the CRC, lower grades of steel should never be used. It may no longer be possible to guarantee the longevity of the complete structure if a material with a resistance class that is too low is used.

Even a single rusty screw can affect the stability of a building and represent a risk to life and limb. An example of this is the accident on 10 May 1985 in Uster/Switzerland, where rusty suspension rods caused the ceiling on an indoor pool to collapse and caused twelve fatalities.

This is the reason why construction planners, engineers, architects and buyers have to take the corrosion resistance of the various materials into account when procuring connecting elements. This is the only way to meet the corrosion protection requirements placed on the components.

The corrosion load expected for a building or a single component needs to be checked in advance. This is because the corrosion load in seawater environments or swimming pool environments that contain chloride is much higher than in other areas. A2 stainless steel may be sufficient for a moderate corrosion load, while you have to use materials such as 1.4529 (CRC V) with very heavy loads.

Due to the standard actualization of ISO 3506-6:2020 (guideline for the selection and characteristics of stainless steels and nickel alloys for fasteners) the materials of the corrosion resistance classes CRC IV and CRC V which we have on stock, are now classified to the new steel grades A8, D8 and D6 as well.

A simplified classification of the most common materials that we stock for you, can be found here:

Material classification to CRC

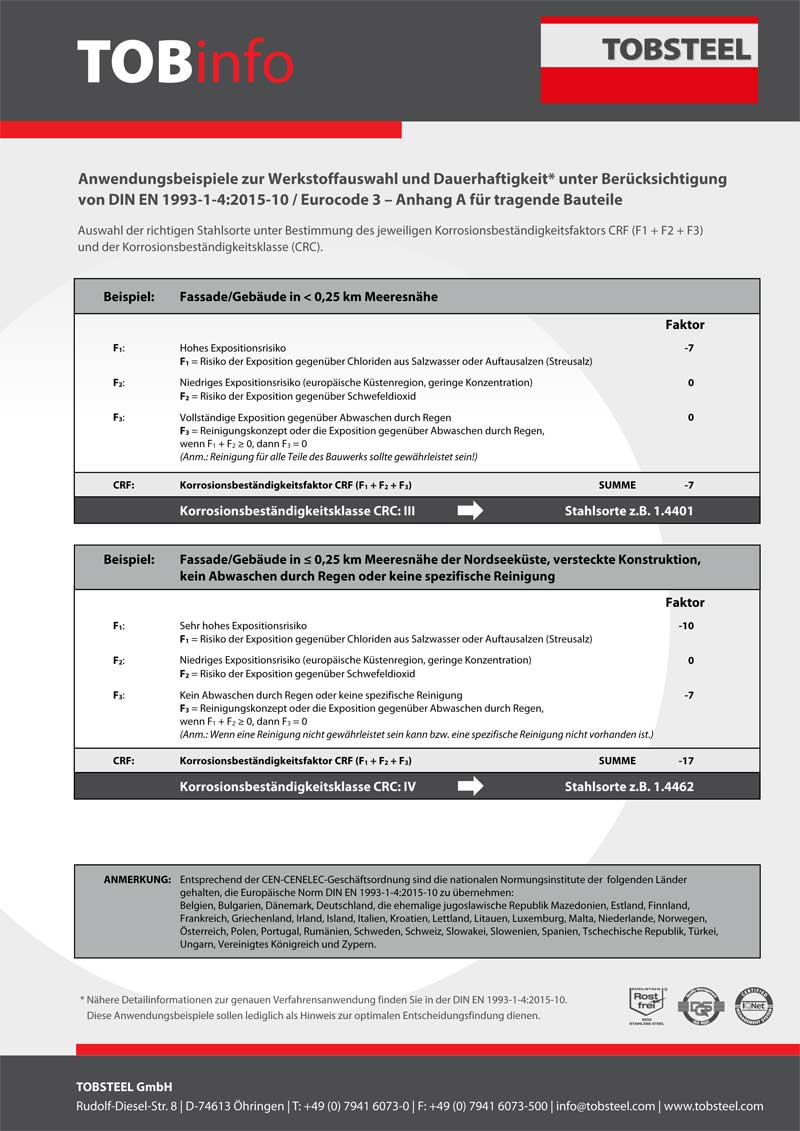

Here are some examples of applications for material selection and durability

taking into account DIN EN 1993-1-4:2015-10/Eurocode 3 – Annex A for load-

bearing components:

Do you have any questions?

Our sales representatives will be glad to assist you and advise you further if you have questions about the choice of materials and CRC classes.

We have suitable materials in stock for you for all your corrosion resistance requirements.

Our Sales Team will be more than happy to help you further:

T: +49 7941 6073-0 sales@tobsteel.com